ADS – Parts feeding and orientation systems

Parts feeding & orientation by vibratory bowl feeder, centrifugal feeder, elevator – adapted to the constraints of your operations.

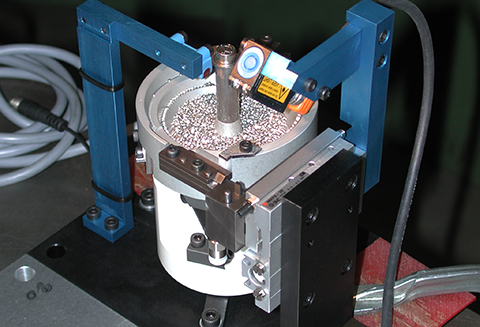

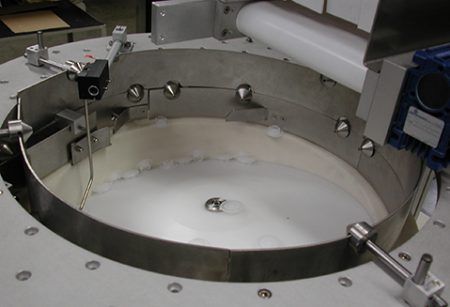

Vibratory bowl feeders

Vibratory bowl feeders are used to feed and orient parts for the next processing step. Stand and bowl can be adapted to your requirements (dimensions, throughput rate, autonomy, etc.)

• Electromagnetic, electro-resonant or pneumatic rotary vibrator.

• Bowl material: polyamide, stainless steel, 304L stainless steel or aluminium.

• Bowl adapted to the type of parts, their orientation and the throughput rate required.

• Overall dimensions between 70 mm and 900 mm.

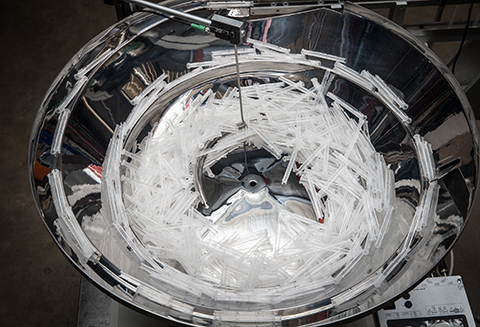

Centrifugal bowl feeders

Centrifugal bowl feeders are used to feed and orient parts for the next processing step at high feed rates – up to 1000 parts per minute depending on the application and type of part.

High feed rates, low noise Available in 500, 700, 900 and 1200 mm versions.

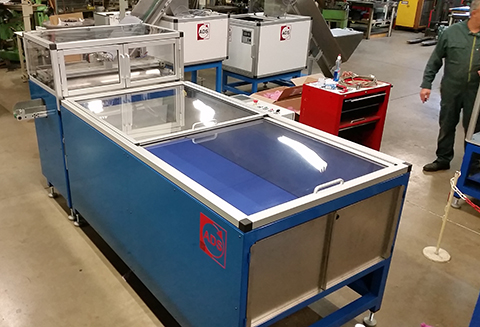

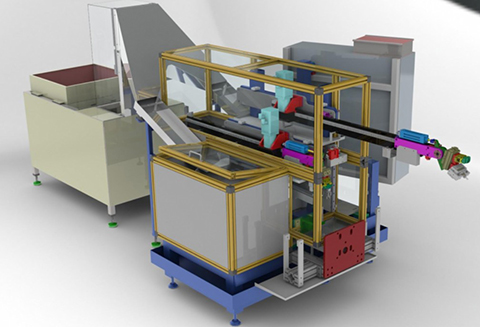

Blade elevators

Blade elevators consist of a storage section and an elevation section.

They are used to raise parts by means of a sequence of fixed and mobile blades, before the parts are selected.

Available with electric or pneumatic drive systems.

Adjustable height and inclination.